The CCL-XTU: the most accurate and fastest measurement device on the market

The CCL-XTU represents an enormous advance in copper loop testing technology and boasts unparalleled levels of measurement accuracy and speed.

CCL worked with a dedicated team of highly trained specialist hardware engineers based in Dresden, Germany in order to develop and build the most advanced automated test system available on the market today, the CCL Cross-Domain Test Head Unit (CCL-XTU).

Extensive testing and deployment give us the confidence to state openly that the CCL-XTU is easily the most efficient copper loop testing device on the market.

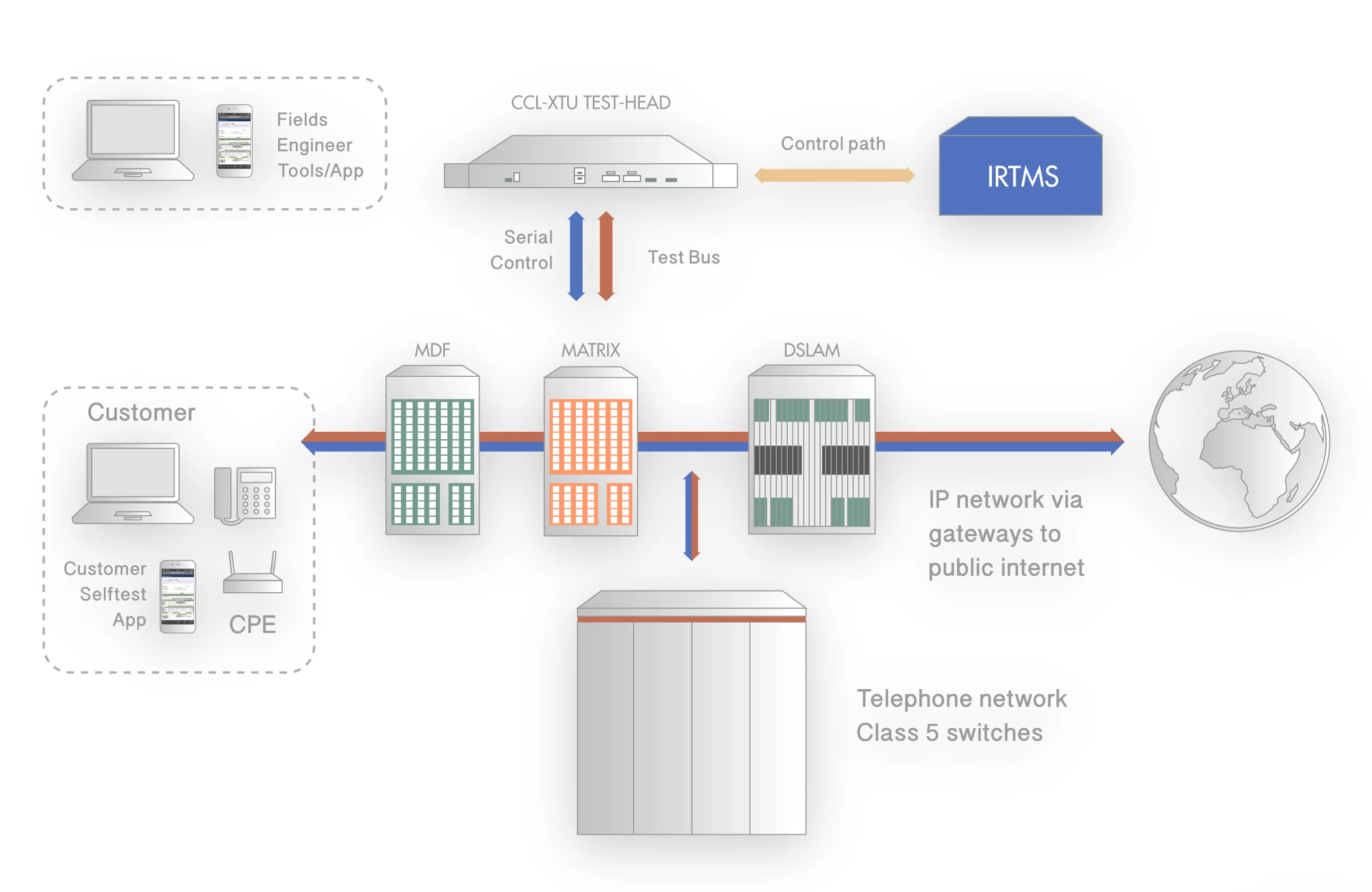

The CCL-XTU is designed to complement our Intelligent Remote Test Management System (IRTMS) element management system as part of our Next Generation Networks product-line, but the CCL-XTU is also sold independently of IRTMS, allowing our clients to either choose their own element management systems or to provide their own controlling software.

The centralised, automated test system addresses all the fundamental issues the copper plant poses as triple play service provision advances. Not only will it fully equip networks to support IPTV, VoIP and DSL and high bandwidth provision, it will also reduce repair times by means of accurate, speedy and efficient testing whilst simultaneously increasing the quality of service.

Investment in the CCL-XTU represents an unparalleled and cost-effective way of upgrading the copper loop infrastructure so that telecoms service providers can deal with the challenges of the twenty-first century.

CCL-XTU Deployment Scenarios

Fixed External Matrix: Central Office Solution

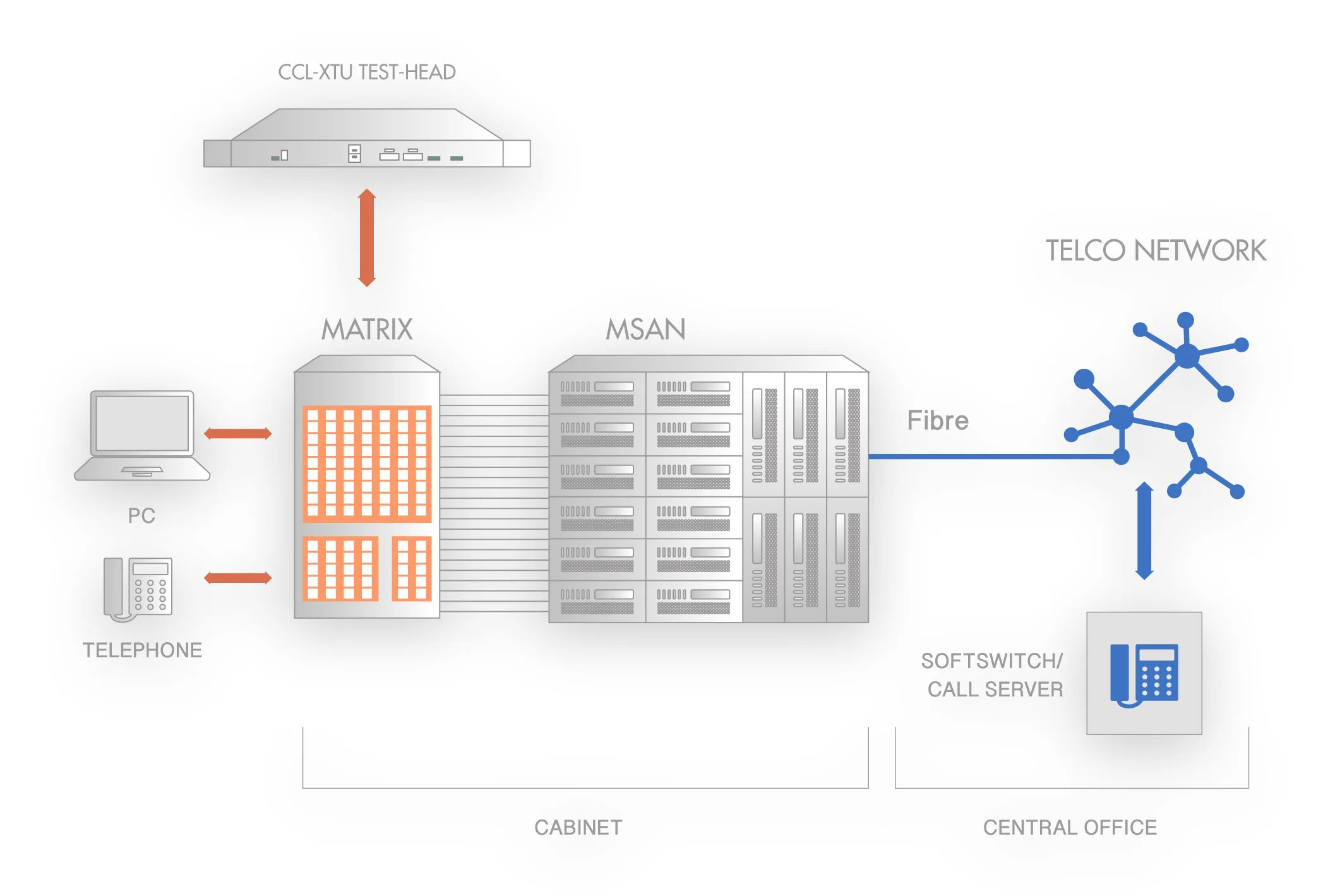

Fibre to the Cabinet (FTTC) Solution

Mobile App Control Interface

IRTMS Mobile App Control Interface. iPhone / Android For Field Engineers

CCL offers clients both iPhone and Android mobile applications to enable field engineers to access the IRTMS element management system from smartphones.

Whereas in the past a complicated and expensive toolkit was needed by engineers when setting up and testing conditions on the line, the outsourcing of field testing to third party organisations has led telecoms service providers seek to keep the operational cost of equipping field engineers to a minimum.

Our smartphone application allows for deskilling of the field testing process and reduces the cost and complexity of engineers' toolkits. This in turn reduces telecoms service providers' operational costs. Field engineers need only bring with them a very basic toolset (which would typically include a resistor pack, pliers and punch down tools) when using their smartphone applications to show where the fault lies in relation to the exchange.

Additional test measurement and safety functionality beyond the capabilities of our competitors’ offerings

The CCL-XTU has the ability to detect and localise the source of metallic noise and longitudinal noise on the copper plant.

Metallic noise emanating from a fault on the copper plant impairs the digital subscriber line to the extent that the end consumer’s telephony experience and DSL internet experience are impaired, often seriously.

Unusually, the CCL-XTU can be used to help pinpoint the source and the strength of the noise, enabling the telecoms service provider to dispatch an engineer to the precise location of the fault in order to effect a rapid repair.

Longitudinal noise can be precisely measured and resolved in much the same way as metallic noise with the help of the diagnostic functionalities of the CCL-XTU. This is particularly important in jurisdictions in which theft of copper grounding cables is an issue: live wires in the field, exchanges or elsewhere pose a health and safety threat to telecoms staff and the general public.

Live wires and cable theft also cause external foreign voltages on lines and the CCL-XTU is able to detect voltages on the line.

The CCL-XTU is the most accurate copper loop testing device available on the market today. Whereas measurements of other test devices fail with differing degrees of regularity, the CCL-XTU boasts leading rates of accuracy some which, in turn, reduces operational costs and repair time. In this way, the CCL-XTU increases quality of service and presents prospective clients with the opportunity to gain competitive advantage over rival telecoms companies.

Sophisticated copper plant testing functionality fit for next generation networks

Whilst advances in voice and data transmission technologies have transformed the telecommunications industry in recent years, efficient copper plant networks remain the backbone of telecommunications operations worldwide.

Technologies such as IPTV, VoIP and DSL depend for their successful deployment on complex and ever more rigorous transmission standards in the copper plant.

The need for copper plant networks with sophisticated testing functionality cannot be overstated. The costs associated with them remain among the heaviest all telecoms organisations carry and efficient testing functionality can rapidly achieve return on initial investment. Pressure from competitor telecoms service providers to drive down the cost of voice and data services coupled with increased regulatory burdens to not only to reduce repair times but also to improve service quality necessitate efficiently run copper plants which keep maintenance costs as low as possible.

Fully Automated Testing Solutions

Notwithstanding all the advances in copper loop testing in recent years, many telecoms companies continue to rely on field-based testing with the use of handheld testing instruments. Whilst these methods are mostly effective they are both inefficient and expensive: they require enormous numbers of man-hours of highly trained engineers and they are time consuming.

A sophisticated copper plant with fully automated testing functionality is a prerequisite for those telecoms service providers seeking to pursue business strategies fit for the twenty-first century strategy.

Ageing copper plants are unable to keep pace with technological advances in the sector. Without testing solutions which maintain current and future demands on the copper plant consumer demand for technologies such as IPTV and increased data rates cannot be met.

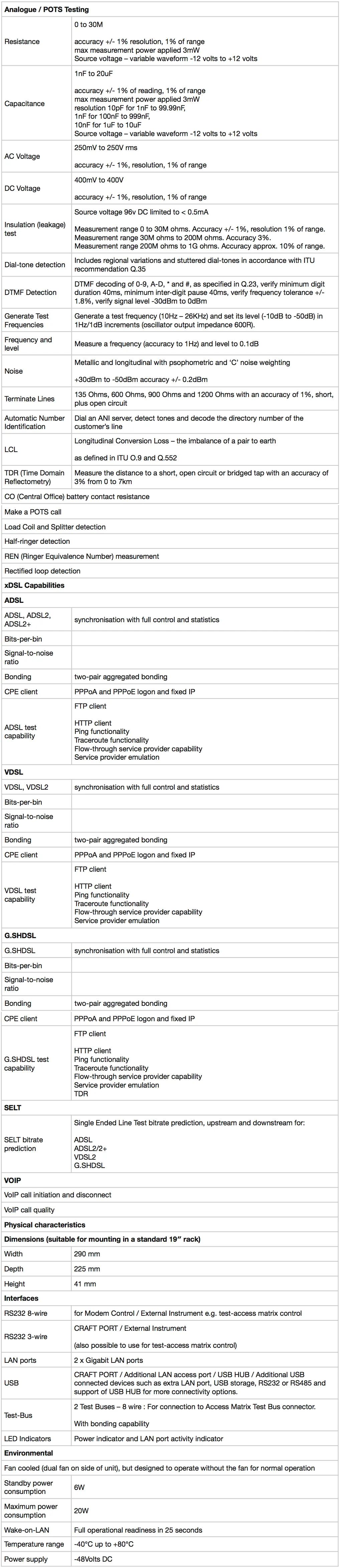

Technical detail

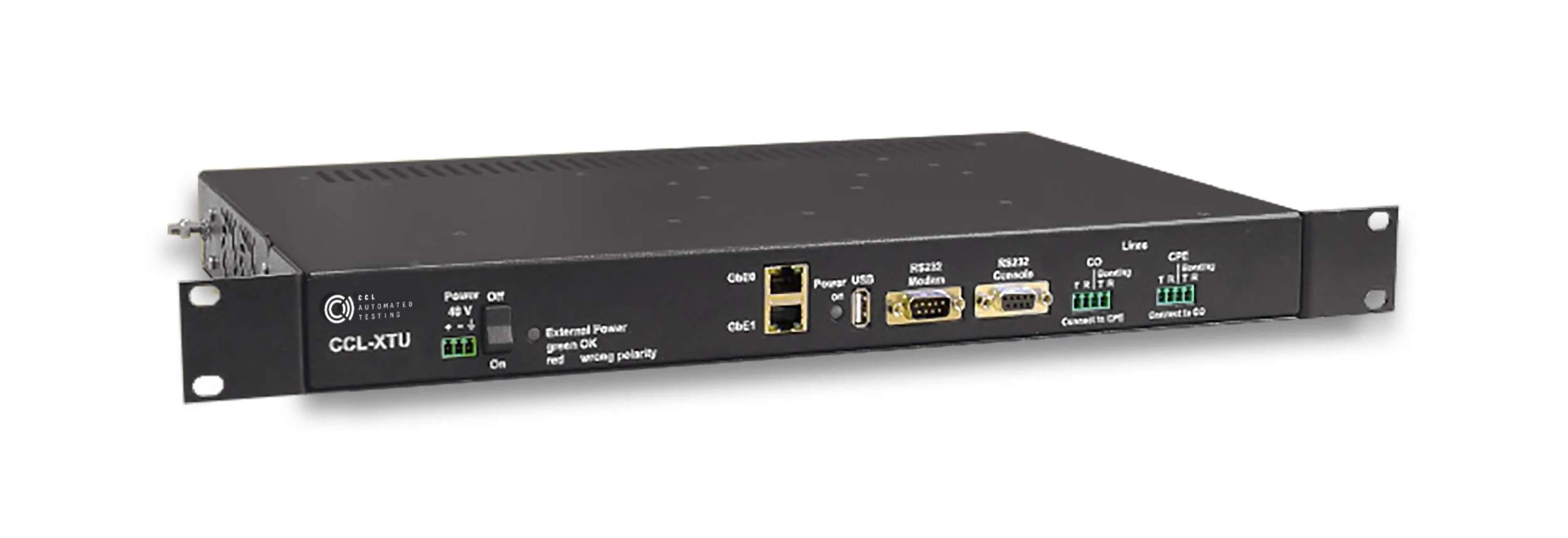

The CCL-XTU is a low-cost, power-efficient, high performance voice and Digital Subscriber Line (xDSL) test head designed both for central office and street-cabinet operation.

CCL-XTU capabilities

ADSL, ADSL2, ADSL2+, VDSL2 Service Assurance Testing

SHDSL Service Assurance Testing

Voice/POTS Service Assurance Testing

Replacement of analogue private circuit test TMUs

Major technical advantages of the CCL-XTU

Tests are fast: a full both-way POTS test completes within 30 seconds including all analogue measurements, dial-tone detection and break dial-tone.

A full both-way xDSL test performing synchronisation, full performance statistics, log-on, FTP, ping, trace-route and web-get is typically performed within 120 seconds

Measurements are very accurate and repeatable.

Voice/POTS tests execute completely independently of the xDSL test engine. A single CCL-XTU can act as though it were two independent test heads conducting a POTS test on one customer line and an xDSL test on another customer line simultaneously.

The CCL-XTU performs simultaneous xDSL testing towards the CO and CPE – this halves the time taken to perform end-to-end xDSL tests. This facility is available for VDSL2 / ADSL / ADSL2 / ADSL2+ and G.SHDSL and significantly boosts testing performance.

The CCL-XTU supports dual line bonded tests (using two pairs of lines to the customer from the exchange CO/MSAN hardware). This facility is available for VDSL2 / ADSL2 / ADSL2+ and G.SHDSL testing.

The CCL-XTU uses commercial xDSL chipsets from Lantiq, a leading manufacturer of xDSL chipset products, giving excellent VDSL2 / ADSL / ADSL2 / ADSL2+ / G.SHDSL interoperability to a large range of customer equipment, DSLAMS and MSANS.

The CCL-XTU allows for flow-through testing from Customer CPE to Test Head CO and onward Test Head CPE to DSLAM/MSAN. This allows the Test Head to observe the Customer CPE internet traffic including the PPPoE login stage if required. This is a feature unique to the CCL-XTU. Nearly all Service Provider Emulations implemented in Test Heads do not fully work because the Customer CPE equipment does not reacquire the network IP address following a successful synchronisation especially if synchronisation was lost just recently (the timing depends upon the lease time granted by the Telco DHCP server).

In-band communication control of the CCL-XTU using either xDSL or G.SHDSL is supported. This greatly simplifies deployment within remote street cabinets.

In addition to the standard serial and LAN interfaces, the CCL-XTU has USB to provide significant options for additional external device connectivity. For example, additional LAN interfaces, RS232 for control interfaces to Circuit Access Switches (Test Access Matrices), USB Modems or even RS485 interfaces.

Modular construction – the CCL-XTU can be supplied with or without the VDSL+ADSL and/or SHDSL modules.

CCL-XTU is unencumbered by license costs or rights-to-use restrictions.

The CCL-XTU is a suitable replacement for the Harris RTU (Remote Test Unit) models 105 and 107A/F as well as Spirent, Tollgrade and Terradyne testing equipment.

Further technical information

Please contact us if you would like to request further information on the CCL-XTU and how CCL can help with your line testing requirements.